The innovative machine vision solution for flow-wrapping machines

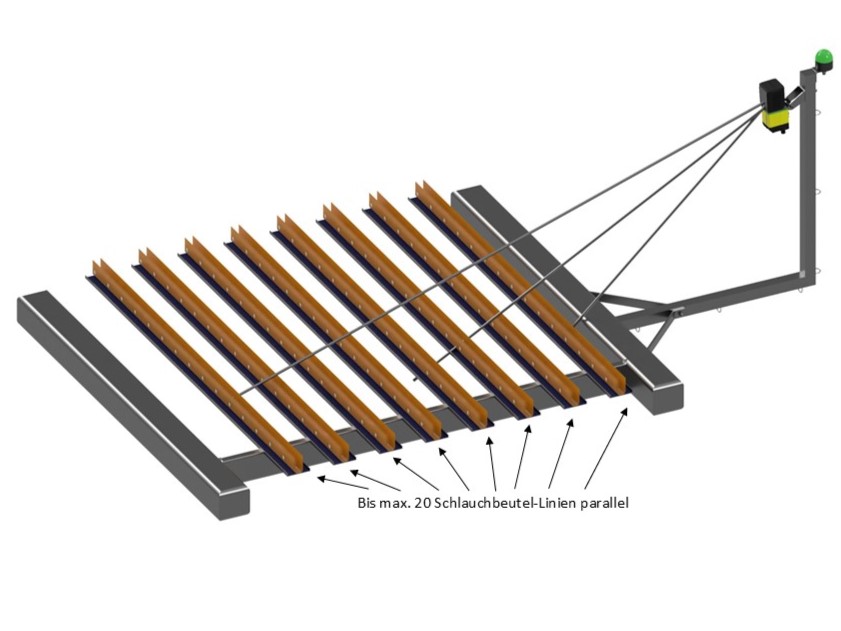

With our new AIT Pack, Track & Check machine vision solution, we optimize packaging processes to a new level. Particularly suitable for flow-wrapping systems with up to 20 parallel lines, our system offers high-precision and efficient quality control for the food industry and many other sectors.

Challenges of packaging inspection

In production lines with high throughput, different products are often conveyed in parallel on several belts. The different pillow packs are inserted manually. Before the packaging is sealed, it is essential to use automated code reading to ensure that the right product is in the right packaging. This check minimizes returns, reduces risks for end consumers – e.g. due to incompatibilities such as nuts – and ensures maximum safety and quality.

Previously, this task required the use of several scanners attached to the side of the webs, which was time-consuming and only partially reliable.

Our solution: One scanner, maximum precision

The AIT machine vision software controls the powerful Cognex HSSM mirror scanner, which covers production lines up to 2 meters wide with just one device.

- Optimum viewing angles for precise detection.

- Minimal light requirements: Ambient light > 500 lux is sufficient, no external light required.

- Quick and easy set-up, making installation particularly user-friendly.

- Good accessibility to facilitate maintenance and inspection.